Part Exchange your machine

- We collect your machine

- Best price guaranteed

- No hidden fees

To get your part exchange price, complete the following steps in order to receive an accurate quotation.

- There has been an issue!

Product Details

The Janome 2000CPX is a special coverstitch machine. It combines industrial performance with the ease of home sewing.

This machine is different from traditional overlockers. The design makes professional cover hems and decorative stitches. These stitches can match those found in ready-to-wear clothes.

The machine operates with up to three needles and four threads. It creates wide triple cover stitches, double cover hems, and single needle chain stitches.

The 2000CPX mixes the power and speed of industrial cover hem machines with the easy design of home sewing machines. This unique method helps sewists get high-quality finishes on knit fabrics, hems, and seams. It does this without the usual complexity of commercial machines.

This comprehensive review examines the machine's build quality, advanced features, and real-world performance across different fabric types. The 2000CPX has special features like the Seam Tightening System and a free arm. These technologies help make home sewing projects look professional.

The CoverPro 2000CPX stands apart from other coverstitch machines through its tension switching lever. This feature enables effortless tension adjustments for different fabric weights without manual dial turning.

Ease of Use and User Experience

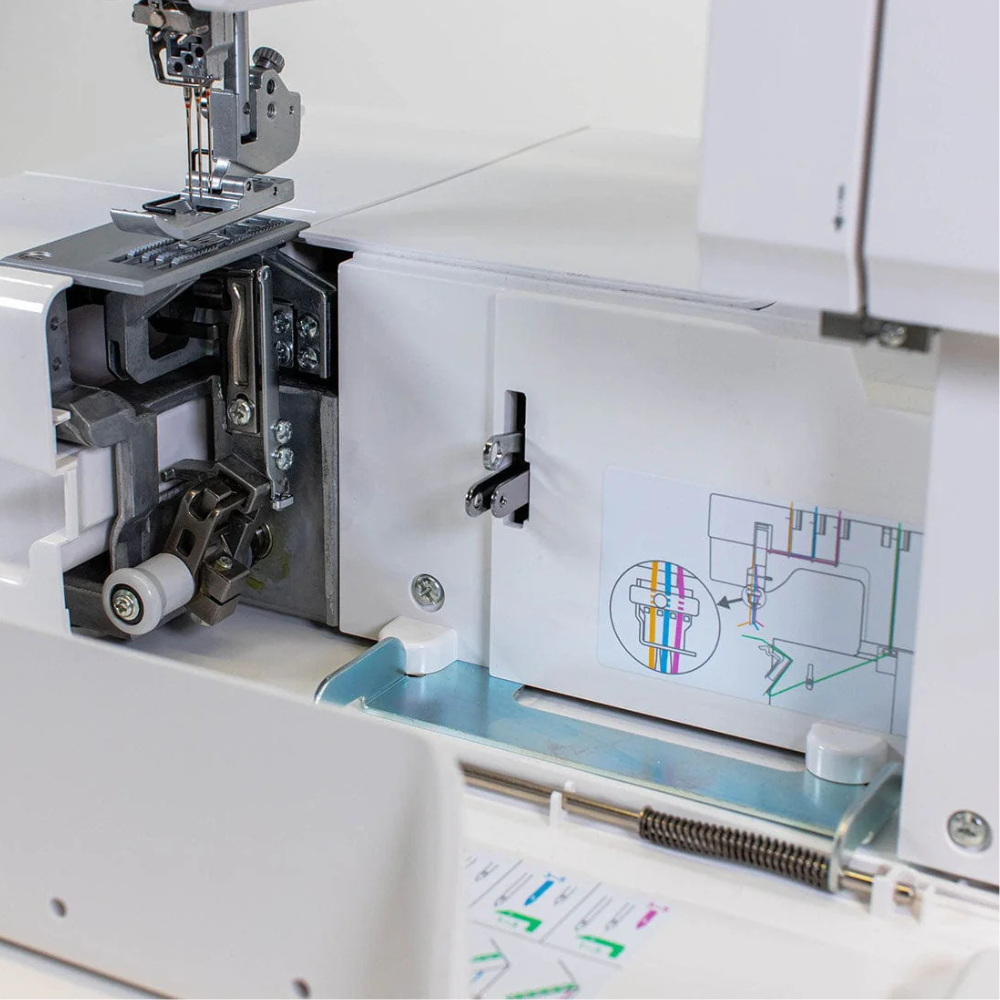

The 2000CPX has a colour-coded threading system that makes setup easy for all users. Inside the looper door, two clear decals help with threading. The first decal shows how to thread the needle. The second decal gives complete threading instructions with color codes.

This visual system works with one needle or three needles and four threads. The color coding removes guesswork during threading. Users say threading becomes easy after just a few tries. The system cuts setup time compared to machines without visual guides.

The tension release device is a significant enhancement for coverstitch machines. This feature lets users quickly adjust looper tension without stopping.

The switching lever is next to the looper tension disc. It moves between tight and loose settings with a simple touch. This removes the need for manual adjustments when changing fabric types.

The device helps users who work with different fabric weights in one project. Lightweight silks need different tension than heavy denim or canvas. This innovation makes the 2000CPX almost as flexible as industrial machines, but it is still easy for home use.

The machine's design focuses on accessibility and clear guidance. The threading paths follow logical steps to avoid confusion during setup. They place thread guides along the threading path. Each guide has distinct colours that match the instruction decals.

The needle threader helps with the last threading step. This tool allows users to thread needles quickly without straining their eyes. The reference chart makes stitch selection and threading easier. It helps both beginners and experienced sewers use coverstitch techniques.

Key Features and Technologies

The 2000CPX brings industrial-grade performance to home sewing through its robust construction and professional capabilities. This design philosophy merges the power of commercial machines with the accessibility of domestic equipment.

The machine makes high-quality triple cover hem stitches quickly and easily. It works well with both light and heavy fabrics. This makes it great for many sewing projects.

The Tension Level Control system gives users precise command over thread tension for optimal stitch formation. This technology eliminates guesswork when working with different fabric types and thread combinations.

TLC offers consistent thread tension, easy adjustments for various fabric weights, and professional results with minimal waste. It prevents issues like loose stitches and works well with stretchy fabrics, ensuring even tension during sewing.

The Seam Tightening System uses a spring-loaded looper mechanism to create consistently tight, professional seams. This patented technology ensures stable stitches across all fabric types.

The spring-loaded system ensures consistent thread tension and smooth stitch formation, preventing loose seams. It helps professional sewers by creating strong, secure seams for activewear and swimwear. It also uses less thread and keeps quality high at different speeds.

The free arm configuration enhances sewing access for tubular garments, allowing easy conversion from flatbed to free arm. It provides extra space for large projects.

It also improves the finish on sleeves and necklines. Plus, it reduces fabric handling. This makes it great for getting professional results on different garments.

Performance and Fabric Handling

The 2000CPX has an adjustable differential feed that ranges from 0.5 to 2.25. This system controls how the fabric moves through the machine. It helps prevent puckering or stretching.

When using knit fabrics, users can set the differential feed higher. This stops the fabric from stretching while stitching. The feed dogs work together to keep the fabric moving smoothly.

For woven fabrics that pucker, a lower differential feed setting is better. This system lets sewers adjust the feed based on how the fabric behaves. This control helps achieve great results on different materials.

The colour-coded threading guides work with the differential feed system. Together, these features make it easier to handle fabric.

The machine works well on medium to heavyweight knits and multiple fabric layers. It can effectively handle denim, canvas, and upholstery materials with the right needle.

The adjustable foot pressure dial lets users change the pressure based on fabric thickness. This feature is helpful when switching between delicate and heavy materials.

Delicate fabrics like silk need lighter pressure settings and careful tension adjustments. The machine's Tension Level Control (TLC) makes it easy to switch between tight and loose settings with one lever.

Machine Build and Specifications

The 2000CPX features a long arm design that provides extended working space for handling larger projects. This industrial-inspired construction creates a sturdy platform for consistent stitching.

The machine's build quality reflects its professional heritage. The frame construction supports high-speed operation without vibration or movement during use.

The compact footprint fits comfortably in most sewing spaces. The machine balances professional capabilities with home studio practicality.

The 2000CPX offers extra large bed space for accommodating bulky projects and multiple fabric layers. This extended work surface makes handling large garments and home décor items significantly easier.

The exclusive free arm configuration sets this machine apart from standard coverhem machines. Users can easily finish sleeves, cuffs, and cylindrical items with professional results.

The free arm slides away smoothly when working on flat projects. This dual configuration provides maximum versatility for different project types.

The generous throat space helps with fabric handling. Sewers can guide materials better, leading to straighter seams and improved stitch quality.

The heavy-duty cover hem machine is built for long-lasting performance. Its industrial-grade parts can handle continuous use without losing stitch quality.

The machine's strong internal parts support high-speed operation. Metal components in key areas resist wear from frequent use and tough fabrics.

Regular maintenance keeps the machine running well. The easy design lets users clean and oil it with little effort.

The build quality shows Janome's focus on durability. With proper care, users can expect years of reliable service.

General Features

1,2 or 3 needles

3mm double needle cover stitch

6mm triple needle cover stitch

Colour coded easy threading

Variable stitch length 1.0 – 4.0mm

Extra large bed space

Unique seam tightening system (STS)

6mm double needle cover stitch

Double chain stitch

Vertical needle drop

Differential feed for difficult fabrics

Tension release device

Your Janome sewing machine has a standard two-year warranty.

Accessories

366401400 Accessory Box

802424004 Lint Brush

200347008 Needle threader

784810002 Screwdriver (large)

792030005 Screwdriver (small)

200217134 Screws for Optional Attachments

624806006 Spool Nets x 4

784223002 Spool Caps (Large) x 4

624801001 Tweezers

C-1033 Foot Control

Needles (ELx705)

You may also like